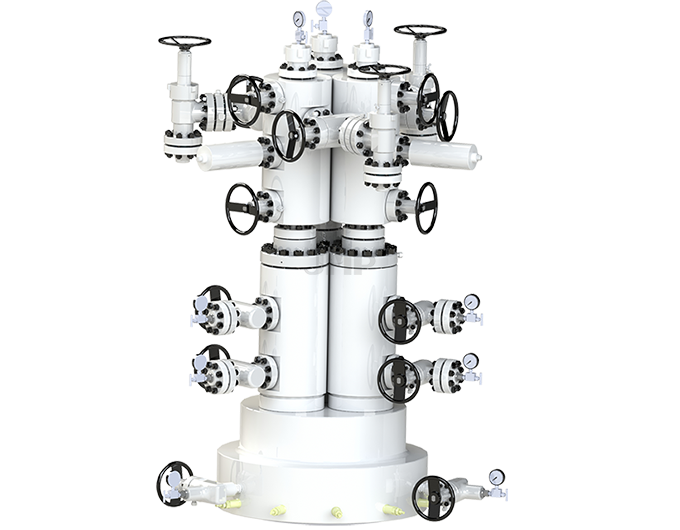

Wellhead & Tree (Oil/Gas)

Fracturing Support Products

Choke and Kill Manifolds

Oilfield Site Services

Integrated Wellhead Solutions

Ultra-High Pressure 175MPa/210MPa Wellhead and Tree (Gas) Solution

Intelligent / Unmanned Platform Wellhead and Tree (Oil and Gas) Solution

Integrated Injection-Production Wellhead Solution

Heavy Oil / SAGD Thermal Recovery Wellhead Solution

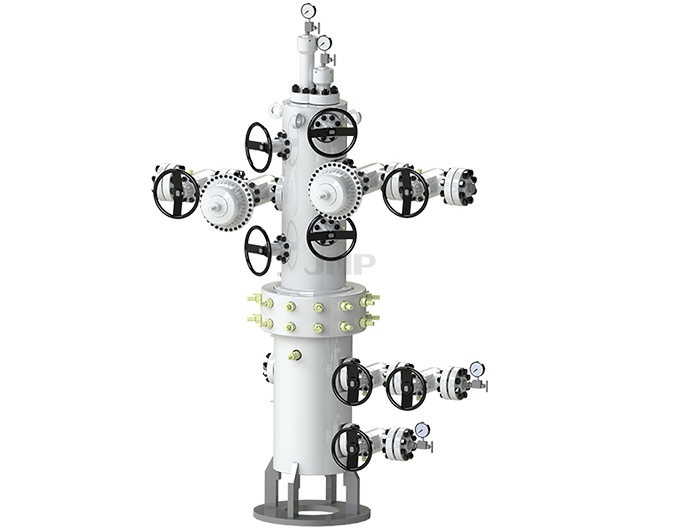

Highly Sour Service High-Pressure Wellhead&Tree (Gas) Solution

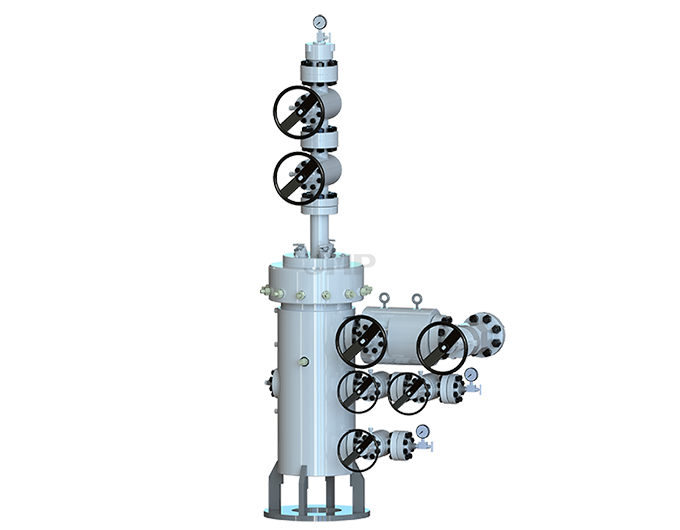

Gas Storage Wellhead Solution

Compressed Air Energy Storage Wellhead Solution

Rotating Test Tree Solution

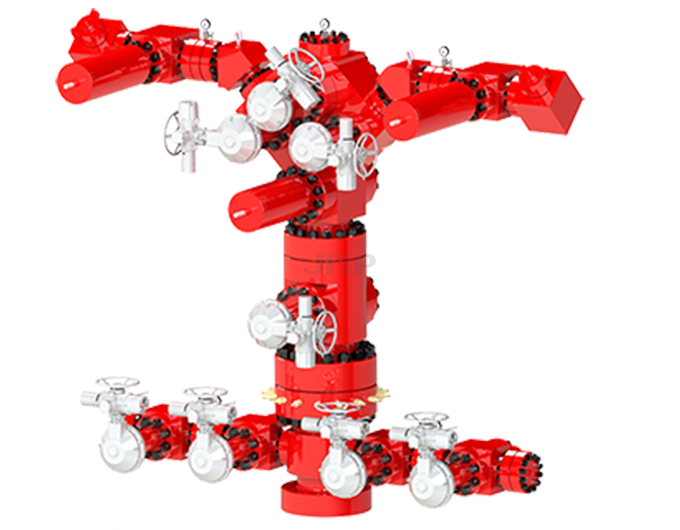

High-Low Pressure Fracturing Manifold Solutions

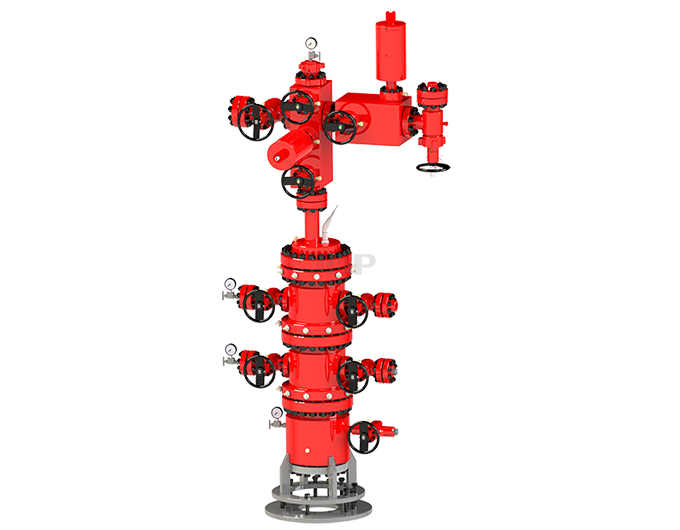

Fracturing Wellhead Solution

Sand Knock-Out Solution

Plug Catcher Solution